INDUSTRIAL HIGH PRODUCTIVITY AUTOMATIC MACHINE DEVELOPMENT

Tecna Machines offers "tailored" or "customized" solutions to the Latin American and global markets. These projects with a high level of innovation are carried out when the product handled presents particular characteristic and requirements for which there are no "Standard” teams in the market to meet them properly. This usually happens when the product also presents novelties.

For more than twenty-five years, the company has always regarded innovation as the most important tool enabling us to place our services one step ahead of the existing suppliers. We seek to increase the engineering and design development capacity, which are key elements in the production of powerful and reliable machines.

There are EDD (ENGINEERING, DEVELOPMENT AND DESIGN) work teams highly specialized in:

- 3D mechanical modeling.

- Design of mechanical devices and their electrical or pneumatic integration.

- Design of functional sets for automatic machines and their functional pieces.

We use state-of-the-art tools:

- Simulation of three-dimensional digital operation.

- 3D scanning for reverse engineering.

- Mechanical Prototyping with 3D professional printing.

CASE STUDIES

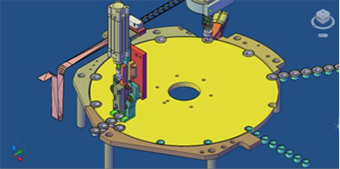

BASIC ENGINEERING

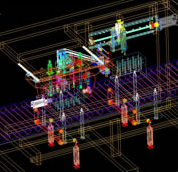

Image of an indexing plate scheme in its Basic Engineering stage.

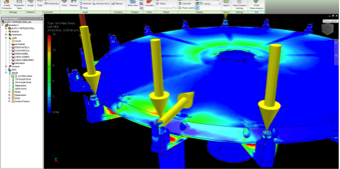

CAD-CAM-CAE SYSTEMS

Analysis of areas of effort, simulating the machine in process.

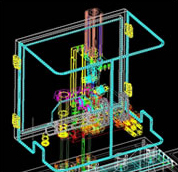

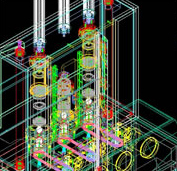

MECHANICAL SIMULATION

Simulation of functional sets.

It is important to stress the interaction between the DESIGN sector and the 3D PROTOTYPING, MACHINING AND MOUNTING sectors.

Development and completion times are carefully planned in order to guarantee the delivery time, including the implementation, the adjustments in our premises and the operators´ training if necessary.

As examples of customized machinery:

Special Project AVON.

Special Project for FILTROS MANN + HUMEL

Special Project for PEUGEOT