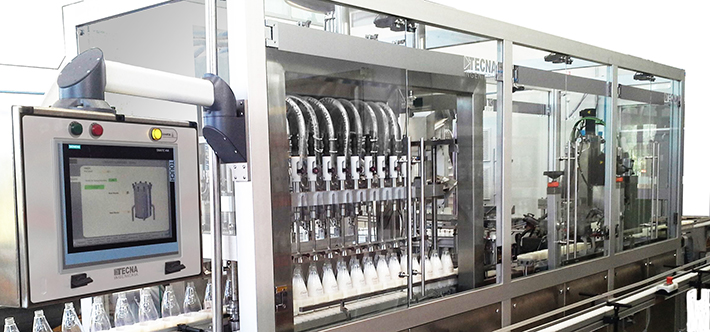

FILLING PACKAGING MACHINES

AUTOMATIC MODULAR FILLING FOR LIQUID OR VISCOUS PRODUCTS.

These machines are designed for flexible product and market strategies with automated processes adaptable to various needs.

Formats can be easily and rapidly changed, favouring notably the Cosmetic and Pharmaceutical industries.

Only the units to be used (cleaning, closing, among others) are acquired.

Production ranging from 50 to 120 pieces per minute.

The machine has a basic unit and various operating units.

The design is based on a modular grid, which allows simple incorporation or elimination of functions in any position of the system.

| FEATURES | |

|---|---|

| - PRODUCTIVITY: | 60 pieces p/min. |

| - FILLING VOLUME: | up to 1.000 ml. |

| - CONTEINERS: | ø 30-100 mm / 30-270 mm high. |

| - CAPS: | ø 15-95 mm and 10-50 mm in height. |

| - TYPES OF CAPS: | Screw, pressure, pump spray, aluminum seal. |

| - FORMAT CHANGE: | Automatic system. Full servo asistance. |

| - CIP: | Automatic filler Cleaning system (optional). |

| - FILLING TECHNOLOGY: | Rotary pumps or flowmeters. |

Modular automatic machine for filling liquid products

Filling / lid placement / labeling / Crimping / covered by screw or pressure

Filling machine liquid products

The design is based on a modular system, allowing simple incorporation or elimination of functions.

This machine is designed for flexible product strategies and market, with automated processes adaptable to the most diverse needs.

Measuring filling volume is controlled by solenoid valves and mass flowmeters.