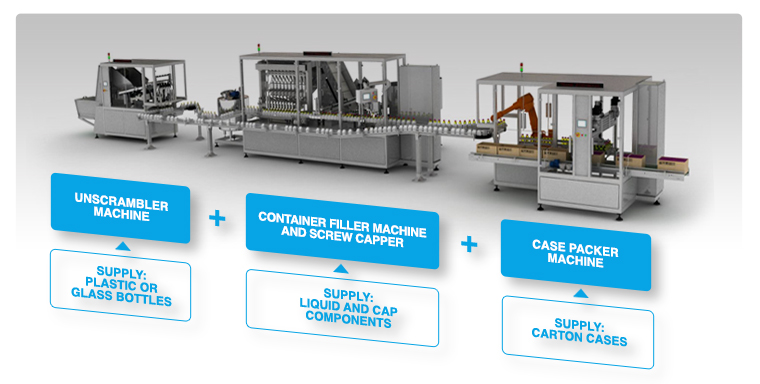

TURNKEY PAKAGING LINE

Production Line

Complete production line: Filling, Cerrado and Embedded product.When an industrial company decides to launch a new production line is recommended that it do planning the same in a continuum form from the first process to the last one.

While it may be staged, it is not appropriate to implement the layout in successive improvised machines that are added to complete the line.

Advantages of the line’s balance

In production lines set up for multiple machines or workstations, the production capacity is determined by the machine or the station of smaller capacity and stability.

To avoid machine downtimes delaying productivity of the line, you need to implement a comprehensive project taking into account all the processes involved, selecting compatible technologies.

Main Characteristics::

- Flexibility in changing formats (Multi-Format)

- High compatibility between machines

- High Productivity: 100 p/min

- Low unit cost - Modular units

Short operational description:

The “Ordaining Packaging Machine” is carried in a bulk. This plastic pucks deliver the product in the correct position. From there it goes to the next "Filling Capping Machine" that fills the corresponding liquid, and then assembling screwing the cap. Then, continue along the conveyor belt to the “machine packer” where a robotic arm making the containers, removing them from the pucks and a Pick & Place device, then putting in the carton. Empty pucks continue down the conveyor belt to restart the whole process again.