Assembly machines | Cap closing machines | Cap lining machines

(Wadding machines)

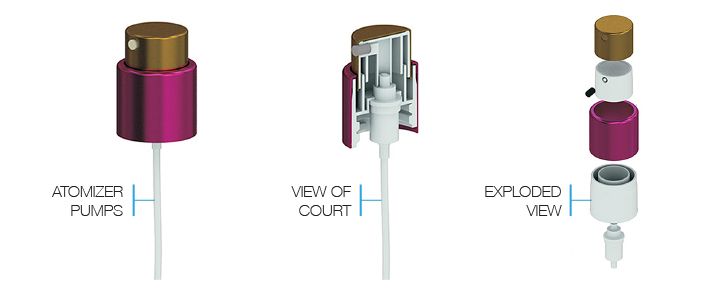

Tecna Machines is a current leader in Latin America in terms of the component assembly process for perfume atomizer pumps and dispensing pumps (dispensers).

ASSEMBLY MACHINES of cap components

Since we started in 1995 by manufacturing Assembly Machines of components for pumps and dispensers, we have developed multiple solutions for the industry, with the latest technology applicable to production means, such as rotary continuous motion assembly machines, indexed machines with robotic integration, complex sorter-feeder and vision cameras of high productivity. Currently, the main activity of the company is the manufacturing of Assembly Machines of components for Pumps and Valves.

ROTARY CONTINUOUS MOTION ASSEMBLY MACHINES

Some products and processes require a perpetual cycle machine. In this type of machines, components are assembled over a rotor and they continuously turn as they are commanded by fixed mechanical cams.

Pneumatic drive systems are not necessary in the assembly plan. Therefore, it is possible to work with high production levels, about 16.000 pieces per hour, delivering the verified product by high speed cameras and different kind of sensors.

ASSEMBLY MACHINES OF INDEXED MOTION

The pieces that make up the final or finished product are assembled in successive phases in a rotating central plate of indexed motion.

There are assembly and quality test phases apart from the loading phases.

At the end of the process, the pieces that do not meet all the requirements are automatically disposed.

CAP LINING MACHINES

Cap seal placement

Our Cap Lining Machines place hermetic seals into caps by means of liner coils or pre-cut liners. Tecna Machines designs and manufactures Cap Lining Machines for punching liner discs from the supply and placing them into the caps, at speeds up to 1.100 caps per minute, depending on the cap size and design.

Tecna Machines has tools designed for cutting and placing various types of disc configurations, with machines of up to 6 punches.

Currently, Tecna Machines offers six different models of Cap Lining Machines to suit different production goals. All our machines can work between 150 and 200 cycles per minute.

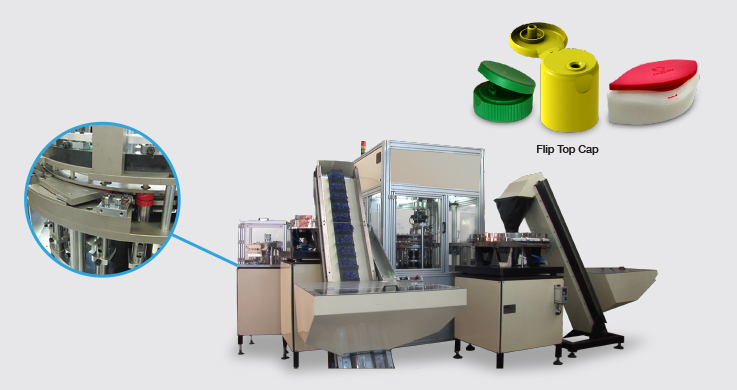

CAP CLOSING MACHINES

In Tecna Machines, we manufacture Flip Top Cap Closing Machines with a production ranging from 3,500 caps per hour -in indexed machines- to 16.000 caps per hour -in perpetual rotating motion machines:

- Closing of Flip-Top caps for different industries.

- Closing of dispenser caps.

- Closing of caps for drink bottles and viscous products packaging.

- Closing of caps with different styles of hinge.